For many years, metal was considered one of the most durable materials, so not only necessary things were made from it, but also protective equipment - from knightly armor to helmets of soldiers of both world wars.

However, progress does not stand still, and a little more than half a century ago a material was invented whose properties are superior to iron in the desire to protect from injury. The most amazing thing is that it turned out to be fabric, albeit from an unusual fiber.

We are talking about Kevlar - a material that can protect against a bullet or knife better than steel.

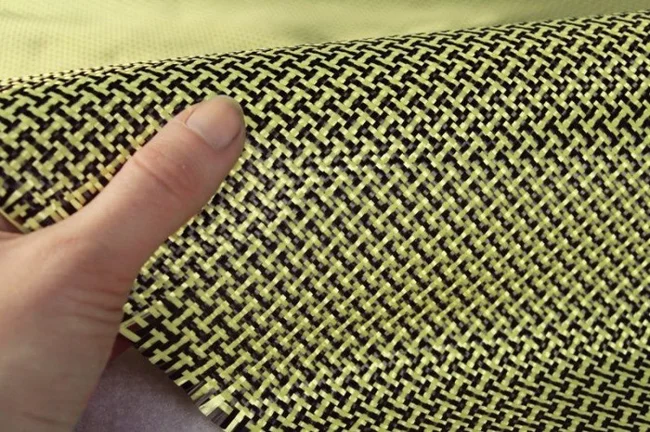

Kevlar is the socially accepted name for armid fabric - that is, one that is made from para-armide fiber. In fact, it is a special-purpose synthetic product, which is often used to create protective clothing and personal protective equipment. This range of its application is determined by its unique characteristics, first of all, amazing strength.

The history of the creation of this unique material began in 1964 at the American chemical company Dupont. Then the local specialists were engaged in quite interesting work: they needed to develop strong but light polymer threads, which could later replace heavy steel cord in car tires. The ultimate goal of such a solution would be to save fuel. Among the company's chemists, Stephanie Kwolek's group also worked on this task. They worked with polyaramids, which are rod-shaped molecules.

In the process of creating polymer fibers from polyaramid, which is difficult to melt, we had to settle on solution spinning technology. For a long time, Kwolek tried to find the solvent necessary for this, but the one she selected did not suit the spinning engineer, because it was not the kind that was usually used either in consistency or in impurities, and he was afraid that its use might suffer as a result equipment. After much persuasion, the engineer finally agreed to try, and what happened impressed everyone - the thread was successfully pulled, and its strength was quite promising even before the stage of testing on devices.

The resulting fibers were sent for testing. However, after seeing the results, Stephanie Kwolek at first thought that the equipment was faulty - the indicators were so high that no one simply believed in them. And only when repeated measurements confirmed the first figures, it became clear: the new material was so phenomenal that its tensile strength was several times greater than that of metal. The complete technology for producing fiber and fabric, called Kevlar, was developed in 1965, and a few years later it began to be produced on an industrial scale.

Since Kevlar began to be mass-produced, it has come in several varieties, each with unique characteristics, applications, and even color. The main types that are used most often are seven:

K29 is the most common modification, used in the production of workwear, military uniforms, and sports equipment;

K49 - used in the manufacture of composites, in shipbuilding and aircraft construction, in the cable industry, as well as in the production of plastics;

K100 - Kevlar, which is painted in different colors (other types are usually black);

K119 – used in the production of rubber products, including car tires;

K129 is a reinforced fiber that is used in the production of body armor and helmets;

KM2 and KM2+ - aramid fiber with improved characteristics, has found application in the military-industrial complex.

Today, the scope of application of Kevlar is simply enormous: cables, parts and bodies of vehicles, sails, skis and even tennis rackets are made from it. But still, the most famous and widespread area of use of heavy-duty fabric is the production of protective clothing for military personnel, police officers, firefighters and many others. It is Kevlar body armor that is considered the most reliable today. And so far, none of the innovative developments designed to surpass this material in strength have been able to do this on an industrial scale.

Among the lesser-known immediate advantages of Kevlar is the ability to withstand temperatures of up to 500 degrees. In addition, the material can protect against splashes of molten metal, contact with other hot surfaces, and even - albeit temporarily - from open flames. Therefore, Kevlar has long been an integral element in the manufacture of protective suits for firefighters and metallurgists. Its high elasticity properties gave it the opportunity to be used in the automotive industry and sports field. And hygroscopicity, that is, the ability to exchange air, and safety in terms of chemical composition allows the material to be used for special-purpose clothing and shoes, as well as various orthopedic gadgets.

But, like any material, Kevlar also has disadvantages. Thus, aramid fiber loses its famous strength when heated for a long time or exposed to direct sunlight. True, this only happens if it is used intensively for hundreds of hours in a row. Kevlar can lose some of its unique properties when it is wet for a long time, so some of its modifications are specially prepared for such conditions by impregnation with the necessary compounds. However, all these disadvantages are not able to affect the status of Kevlar fabric, which it has been wearing for many years - one of the most durable materials on the planet.

0 comments